Delcam FeatureCAM 2014 R1 20.0.1.40 Review

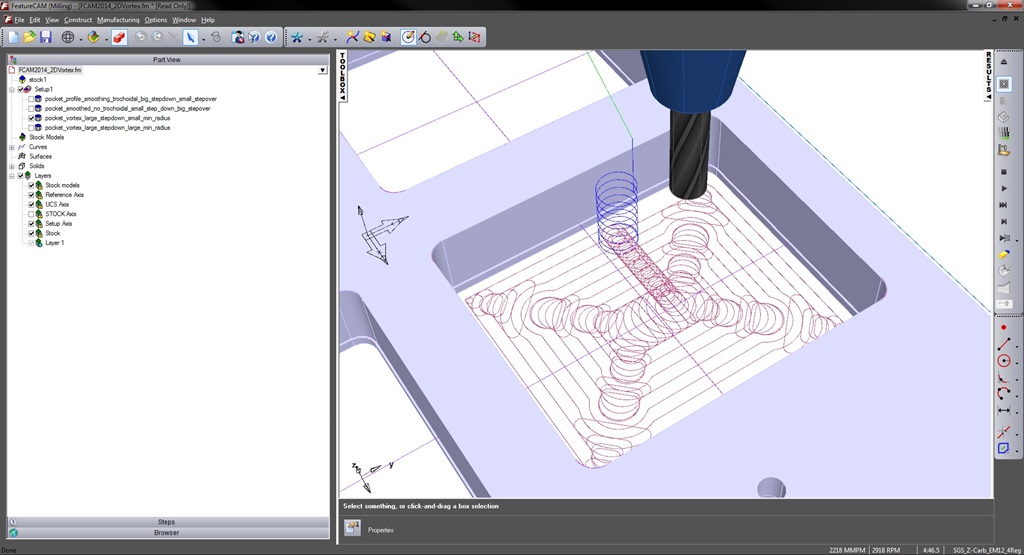

Delcam has developed FeatureCAM, which is a suite of CAD/CAM software which combines cutting edge technology with ease of use and minimizes programming times for parts on mills, wires EDM, lathes and automates machining. It focuses on easier and faster programming with Vortex for 2.5D features, and new options for turning, turn-mill operations and 4-axis rotary machining. The fillets can be added to any sharp corners for turning operations like automatic deburring, which can be done without editing the geometry. As a user, you just have to simply specify the radius to be applied and the sharp corners will be filleted automatically in it. It also has the functionality for automated chamfering of corners. The turning simulation has become more realistic with support for steady-rest and tailstock operations combined with automatic collision detection, this accessory is undertaken automatically during both transfer and cutting operations. The programming of both four-axis and turn-mill equipment has become more easier with the ability to change the index axis part-way through programming as now it can be achieved simply by using that as the new index axis and creating a new user coordinate system.

Now with the improvement in interface it will make easier to use a curve to define start points and plunge points for both milling and turning. Now, you can pick these curves by clicking on them as earlier you had to type the name of the curve in it. It also has more improved probing routines and at the same time support for 4-axis rotary tables has been enhanced to allow 2 or 3 axis operations which can be wrapped around the rotary axis and for two-axis finishing it will give you better machining results and greater programming control. The new features of FeatureCAM 2014 will help you to manufacture parts with more accuracy and greater control and accuracy. The new features includes- additional support for machines with 4-axis rotary tables, Vortex for 2.5D features, New probing routines, Automatic clamp avoidance for NT toolpaths, Support for steady-rests and tailstocks, automatic corner filleting and 2 axis NT finishing strategies. As, it has modular structure wherein each module solves certain tasks and if you don’t require modern strategies for programming, then you can just use the individual modules. It also allows you to import or build item, simulating or creating a processing, identifying the elements of the details like (grooves, pockets, holes etc.), I can also generate NC code control program and with the help of knowledge base processing technology you can increase the productivity of your machining. At the same time, it can select a tool and can calculate speeds, feeds, step and depth of cut very easily. It can determine finishing and roughing operations automatically. In this suite, you just have to just specify the required degree of automation and can change automatically generated processing. FeatureCAM 2014 has extensive library of postprocessors with the ability to create your own or modify existing, built in 3D simulation and has API interface to custom applications and to create a macro programming. The feature based technology to streamline programming makes it a different suite from others available in the market.  So, this feature-based CAM software has new options for turning, four-axis rotary machining and turn-mill operations along with more strategies for easier programming of probing sequences and two-axis finishing.

So, this feature-based CAM software has new options for turning, four-axis rotary machining and turn-mill operations along with more strategies for easier programming of probing sequences and two-axis finishing.

So, this feature-based CAM software has new options for turning, four-axis rotary machining and turn-mill operations along with more strategies for easier programming of probing sequences and two-axis finishing.

So, this feature-based CAM software has new options for turning, four-axis rotary machining and turn-mill operations along with more strategies for easier programming of probing sequences and two-axis finishing.